Allt när det gäller stål och metaller

- Enhet

- Antal

-

- Radmärke

Vill du bli kund?

Ansök om kundkontoProduktinformation

Det austenitiska stålet med beteckning 1.4307 (SS 2352) tillhör den absolut vanligaste typen av rostfritt innehållande ca 18% krom och 9% nickel. Stålet har låg kolhalt, högst 0,03%, vilket betyder att det vid svetsning föreligger minimal risk för nedsatt korrosionsbeständighet intill svetsen.

I form av svetsade rör är 1.4307 standardiserat i SS-EN 10296-2. Tappers lagerprogram omfattar rör med yttre diameter i intervallet 20-254 mm och väggtjocklekar mellan 1,5 och 3,2 mm. Vid tillverkning av rören utgår man ifrån plåt som glödgats, betats och kallvalsats (ytbeskaffenhet är normalt 2B). Efter kapning bockas sedan plåten till rundformat och svetsas i längsled. Svetsmetoden är olika men för tunnväggiga rör tillämpas för det mesta elektrisk motståndssvetsning utan tillsatsmaterial.

Stålet 1.4307 karakteriseras av god korrosionsmotstånd vid kontakt med vanligt, neutralt vatten såväl inomhus som utomhus. Beständigheten mot atmosfärisk korrosion är också god. Denna stålsort utgör dock ett mindre bra val om miljön är sur eller om den innehåller klorider. Då krävs stål med högre legeringsinnehåll.

1.4307 uppvisar såväl mycket bra formbarhet och svetsbarhet så att vid behov utgör kallformning och ytterligare svetsning av svetsade rör sällan något problem. Svetsade rostfria rör underkastas omfattande provning för att försäkra att ingen risk för sprickbildning vid eller intill svetsen föreligger om rören ska kallformas.

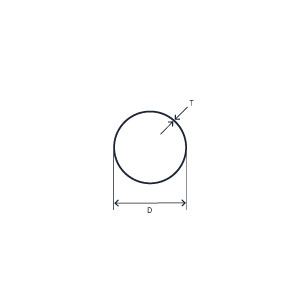

Svetsade rör i stålsort 1.4307 som lagerhålls har efter svetsning antingen glödgats och betats ytterligare en gång eller blankglödgats i skyddsgas. Ytorna, som betecknas W2A respektive W2R i EN 10296-2, är helt metallisk ren utan oxid men svetsen är synlig och svetssvulsten tillåts vara något förhöjd. Toleranserna på yttre diameter (D) och väggtjocklek (T) stipuleras i detalj i EN 10296-2 och EN-ISO 1127 men är som mest ±1% av D och ±10% av T. Rören har god rakhet, med högst tillåten pilhöjd 0,002 gånger längden.